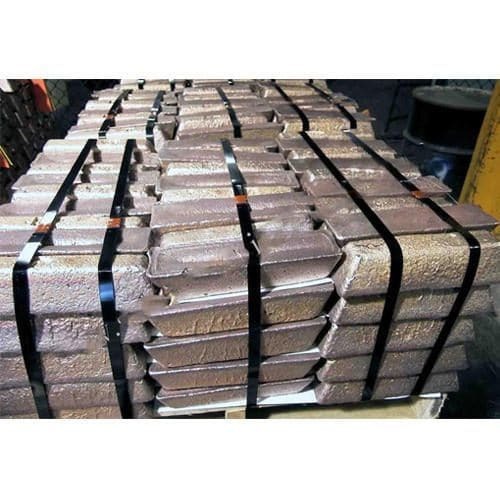

About Tin Bronze Ingots

High quality Tin Bronze Ingots are used in diverse industrial sectors such as automobile, railways, electronic, engineering, and more. We offer a vast gamut of these ingots to meet the industry-specific applications of shipbuilding, construction, casting, and so forth. Composition of Tin and Bronze in the Tin Bronze Ingots are in accordance with the customer requirement. Specific standards such as EN, DIN and others are also assured to reach the highest level of quality while offering products to the clients. Furthermore, features like low maintenance, durability, high tensile strength, and corrosion resistant make our Tin Bronze Ingots suitable for manufacturing valve and fitting.

As a leading manufacturer, exporter, and supplier, we take it as our prime responsibility to offer Tin Bronze Ingots meeting the customized specifications of the customers. High tensile strength and uniform dimensions of our Tin Bronze Ingots are widely appreciated. Above all, we are able to fulfill the bulk requirement of the customers within committed time frame.

Tin Bronze Ingots Features :

- Anti corrosive

- Greater longevity

- High metal content

- Excellent ductility

- Excellent toughness

- Better operational life

- Ideal for valve and fitting

- Excellent tensile strength

- Durable and high efficiency

- Resistant to extreme pressures

- Highly resistant to rust & wear

- Excellent mechanical strength

- Well tested before supplied in markets

- Precise composition of tin and bronze as per international standards

Tin Bronze : Copper Alloy Chemical Composition

CuSn10: Standard: DIN:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

AL |

MN |

SI |

SB |

S |

| 88.5-90.5 |

9.3-11 |

0.8 |

0.5 |

0.15 |

1.8 |

0.05 |

0.01 |

0.1 |

0.01 |

0.15 |

0.04 |

GbCuSn12 : Standard: DIN:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

AL |

MN |

SI |

SB |

S |

| 86-88 |

11.3-13 |

0.8 |

0.5 |

0.15 |

1.8 |

0.05 |

0.01 |

0.1 |

0.01 |

0.15 |

0.04 |

GbCuSn12Ni: Standard: DIN:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

AL |

MN |

SI |

SB |

S |

| 84-87 |

11.3-13 |

0.15 |

0.3 |

0.15 |

1.5-2.4 |

0.05 |

0.01 |

0.1 |

0.01 |

0.05 |

0.04 |

CuSn4: Standard: DIN : Chemical Composition:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

Impurities |

| Rem. |

3.5-4.5 |

0.02 |

0.2 |

0.1 |

0.2 |

0.01-0.4 |

0.2 |

CuSn5: Standard: DIN:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

Impurities |

| Rem. |

4.5-5.5 |

0.02 |

0.2 |

0.1 |

0.2 |

0.01-0.4 |

0.2 |

CuSn6: Standard: DIN:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

AL |

SI |

S |

| 86-89.5 |

5.7-6.5 |

1.2-2 |

3.2-5 |

0.25 |

1 |

0.03 |

0.01 |

0.01 |

0-0.08 |

CuSn8: Standard: DIN:

| CU |

SN |

PB |

ZN |

FE |

NI |

P |

Impurities |

| Rem. |

7.5-8.5 |

0.02 |

0.2 |

0.1 |

0.2 |

0.01-0.4 |

0.2 |

Versatile Applications Across Industries

These tin bronze ingots are engineered for multifaceted use in the steel industry, construction, roadworks, machinery packaging, defense, oil drilling, electrical substations, and bridges. Their alloy composition and quality powder-coated surface enable them to perform reliably under diverse and challenging conditions, ensuring high performance and longevity across applications.

Premium Alloy Grades and Coating

Produced with premium alloy grades like PB1, PB2, CuSn12, and CuSn10, our rectangular tin bronze ingots offer versatility and strength. The powder coating provides an added layer of protection, boosting corrosion resistance and giving a sleek silver appearance. This combination ensures unparalleled functional and visual quality.

FAQ's of Tin Bronze Ingots:

Q: How are tin bronze ingots with powder coating used in the steel and construction industries?

A: Tin bronze ingots are valued in steel and construction for their strength, conductivity, and corrosion resistance. They are utilized in making durable components for bridges, electrical substations, roads, and building structures, as well as in machinery packaging and defense applications.

Q: What is the process for applying the powder coating to the tin bronze ingots?

A: Powder coating is applied through a dry finishing process where finely ground pigment and resin are electrostatically sprayed onto the surfaced ingots. The coated ingots are then cured in an oven, resulting in a tough, uniform, and attractive silver finish that enhances protection.

Q: When should I choose PB1, PB2, CuSn12, or CuSn10 alloy grades for my application?

A: The choice of alloy grade depends on your specific needs. PB1 and PB2 offer excellent wear resistance, while CuSn12 and CuSn10 provide superior tensile strength and conductivity, making them ideal for electrical and heavy engineering uses. Consult our experts to determine the best grade for your project.

Q: Where are these tin bronze ingots manufactured and supplied from?

A: We manufacture, supply, and export these coated tin bronze ingots from India, serving clients both domestically and internationally. Our distribution channels cover a wide range of industrial sectors and locations, ensuring timely delivery and support.

Q: What are the main benefits of using powder-coated tin bronze ingots in industrial applications?

A: Powder coating enhances the natural corrosion resistance of tin bronze alloys, ensuring longer service life and reduced maintenance. Additionally, the process delivers a consistent and aesthetic silver finish, making ingots suitable for high-visibility applications and demanding environments.

Q: How does the rectangular shape of these ingots benefit machine packaging and manufacturing?

A: The rectangular shape allows for efficient stacking, handling, and automated machine processing. This improves workflow, reduces waste, and simplifies transport, making them an ideal choice for large-scale production and packaging operations.